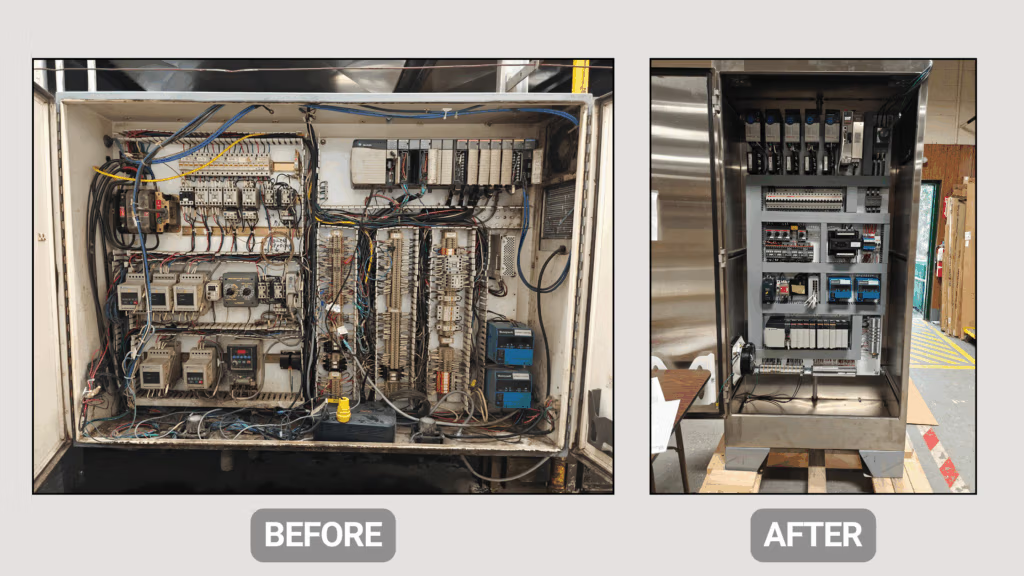

This project spotlight highlights how EDC modernized a legacy pancake production line at Milmar Food Group, improving synchronization, reliability, and operator usability without replacing the existing machine.

Top-down view of EDC’s upgraded servo-driven flipper in synchronized motion—precision pancake flipping in action.

A Look Inside Milmar’s Pancake Production Line

Milmar Food Group produces pancakes, crepes, and stuffed breakfast items that many of us have grabbed out of a freezer aisle without thinking twice about the engineering that goes into creating them. Behind every round, evenly cooked pancake is a production line that has to consistently synchronize movement, timing, and heat.

When one of Milmar’s main pancake depositors and flipping systems began experiencing reliability problems, timing drift, and control failures, they faced a difficult choice. A brand new unit would cost close to $1 million and wouldn’t fit in the existing footprint. Instead, they reached out to EDC, seeking a solution to modernize the existing equipment without replacing the entire machine, all while respecting the unique requirements of a Kosher production environment.

Milmar’s pancake line includes several interdependent stages, each of which relies on precise timing and coordinated motion:

- Batter preparation: Dry ingredients are mixed in a large industrial mixer equipped with vibratory aids.

- Batter transfer: Pneumatic pumps move the mixture to an elevated hopper.

- Depositing: A depositor dispenses batter onto individual griddle plates as they move beneath it. Precise coordination between the depositor and griddle motion is required to ensure consistent pancake size and shape.

- Cooking and flipping: Pancakes cook through the first section on the griddle plates before reaching a servo-driven spatula assembly that lifts and flips each pancake onto the second cooking zone.

- Downstream processing: Fully cooked pancakes continue to a filling station where they may be folded, filled, or layered for various finished products.

This workflow demands tight synchronization between multiple axes of motion. Any misalignment directly affects product quality, yield, and the level of operator intervention needed.

The Problem of Synchronization

As the legacy control system aged, the line experienced progressive drift between the depositor, conveyor, and flipping mechanism. A useful comparison is the familiar experience of driving in the rain: for a brief moment, the windshield wipers may seem perfectly in rhythm with the music on the radio, only to drift out of sync a few lines later. The same thing was happening on the pancake line—motions that initially aligned would gradually shift out of phase.

As drift accumulated, the depositor might lag by a fraction of a second, causing batter to land in the seams between griddle plates. The flipping mechanism could arrive too early or too late, cutting pancakes in half or flipping them off-center. Operators frequently compensated by adjusting speeds “by eye” to bring the system back into alignment, often only temporarily before timing issues reappeared.

Compounding the issue, the flipper’s position encoder relied on a plastic coupling that degraded under heat and misalignment. Milmar was burning through three couplings a month, and when one failed, the spatulas had no idea where they were, creating chaos on the line.

These issues reduced throughput reliability, increased waste, and created a heavy operational burden for staff.

Upgrading to Coordinated Motion Control

It was clear the system needed more than a touch-up. It needed modern, coordinated motion control. Rather than replace the entire machine, EDC implemented a comprehensive controls retrofit designed to stabilize motion, improve accuracy, and provide a modern operator experience.

Controls Platform Upgrade

The existing Allen-Bradley SLC 500 PLC was replaced with a CompactLogix L81 controller. This transition provided:

- Native motion-control capabilities

- Improved reliability and program retention

- Enhanced diagnostic tools

- Better ongoing Rockwell Automation support

Servo Motor and Encoder Integration

EDC replaced the flipper spatula motor with a Kinetix servo motor with an integrated absolute encoder, providing:

- Precise positional control

- Elimination of the heat-sensitive plastic coupling

- Stable home reference without drift

- Consistent flipping angle and timing

A “Home” function was added to the HMI, allowing operators to re-establish a verified position for the spatulas quickly, if needed.

Electronic Camming for Synchronization

To eliminate timing drift entirely, EDC implemented electronic camming. In this configuration:

- The conveyor becomes the master axis

- The depositor and spatula mechanisms follow predefined cam profiles

- All axes remain synchronized electronically rather than through manual speed adjustments

This approach creates a virtual line shaft, ensuring each motion component maintains the precise relationship needed to produce a uniform product.

Overhead shot of Milmar’s depositor dispensing batter with cammed precision onto heated griddle plates.

HMI and Operator Interface Enhancements

A new Rockwell PanelView Plus 7 HMI provided an updated user interface with:

- Simple pancake-size input in inches (4”, 5”, 6”), replacing earlier cryptic numeric codes

- Calibrated control allowing operators to compensate for mechanical wear without complex adjustments

- Clear feedback for interlocks, faults, and system readiness

These improvements reduce operator dependency and make the system more accessible to new personnel.

Food-Grade Controls Design

All new controls were installed in a stainless steel, washdown-rated enclosure, meeting food and beverage industry sanitation standards.

EDC also redesigned interlocks around the batter-transfer system to prevent inadvertent pumping during cleaning or maintenance, addressing a recurring source of downtime.

Integrating Kosher Operational Requirements: The Role of “Rabbi Mode”

With the core motion system upgraded, EDC also addressed an important aspect of Milmar’s Kosher-certified production environment: the facility’s daily burner-lighting routine. Each morning at approximately 5 a.m., the supervising rabbi arrives to light the burners that heat the griddle plates. This early schedule is essential because the griddle requires roughly 45 minutes to reach an even operating temperature. By the time production staff arrive at 7 a.m., the line must be fully preheated and ready for operation.

Several constraints make this startup sequence more complex than it might appear:

- The conveyor must move during burner lighting to ensure the griddle plates heat uniformly.

- The batter hose cannot be connected while the griddle is in motion.

- Sanitation staff often have sections of the machine disassembled during overnight cleaning.

- The rabbi does not operate the machine during production, so the interface must be simple and unambiguous.

To support this process, EDC developed a dedicated preheat sequence, informally referred to on-site as “Rabbi Mode.” This functionality allows the rabbi to safely initiate the warm-up procedure without engaging the full production system.

Key elements include:

- A clearly labeled RABBI BUTTON on the HMI for initiating preheat

- Limited, controlled conveyor motion to promote uniform heating

- Temporary bypass logic for specific depositor interlocks when the machine is partially disassembled

- An intuitive interface requiring no machine operation expertise

This capability integrates the nuances of Kosher operational practice with modern automation, supporting a smooth, compliant start to each production day.

Results: A Higher-Performing Machine Within the Existing Footprint

Today, Milmar’s pancake line retains its original mechanical framework but operates with the consistency and precision expected of a modern motion control system.

Key outcomes include:

- Stable, drift-free synchronization between depositor, conveyor, and flipper

- Improved pancake geometry and reduced waste

- Faster and more intuitive operator setup

- Increased system reliability through servo/encoder integration

- Elimination of recurring plastic coupling failures

- A food-safe controls design suitable for washdown environments

- Startup procedures aligned with Kosher operational requirements

- New complete drawings and alarms for faster diagramming and repair

- Significant cost savings compared to purchasing a new machine

- An estimated 20-30% improvement in uptime

- An estimated $30-40,000 of repair labor and parts saved annually

The result is a machine that looks familiar to operators, yet performs at an entirely different level of accuracy and dependability.

EDC’s modernization of Milmar’s pancake line reflects the company’s broader philosophy: combining technical expertise with a deep understanding of customer processes, constraints, and daily realities. Rather than recommending a full equipment replacement, EDC developed a targeted retrofit that extends machine life, improves consistency, and respects the operational rhythms of a Kosher-certified facility.