Case Study: Precision in Tin Plating

A major metals processor in the Midwest faced a significant challenge in modernizing its tin plating line to enhance productivity, consistency, and operational efficiency. Confronted with the complexities of integrating advanced automation, maintaining consistent product quality, and adapting to a newly relocated plant environment, they turned to Electronic Drives and

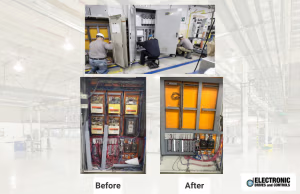

Giving New Life to A Composite Coating Line with Turnkey Solutions

When a leading aerospace composites manufacturer faced the challenge of modernizing a late-1980s coating line equipped with obsolete DC motors and a CompactLogix PLC, they turned to EDC for a comprehensive retrofit and upgrade. The aging system, with components nearly 35 years old, posed significant risks of failure and operational

EDC’s Siemens Retrofit of Wire Annealing Line Enhances Efficiency and Operator Control

Ethicon, a division of Fortune 500 pharmaceutical company Johnson & Johnson, is a global leader in surgical technology, specializing in the production of sutures, surgical staplers, energy devices, and other advanced medical tools used in minimally invasive and open surgeries. At their New Jersey facility, Ethicon was relying on a 1980s

EDC’s Upgrade Ensures Future-Proof Operations for American Biltrite

EDC successfully upgraded American Biltrite’s critical coating line with modern controls during a planned shutdown period, enhancing operational efficiency while reducing the risk of future failures. American Biltrite (ABI), a manufacturer of high-quality protective films and advanced coatings for automotive, construction and flooring industries, faced challenges with their 1980s-era coating

Modernizing Industrial Machinery: A Strategic Approach to Retrofitting with EDC

EDC’s client bought a slitting machine that was in pieces from an auction. EDC engineers were excited to give new life to a line that was in a used equipment warehouse. Case study by EDC Project Manager Joe Maloney Problem Reviving outdated machinery with modern controls demands strategic planning. This

Case Study – EDC’s Modernization of a Ruesch Steel Slitting Machine Control System with Siemens Yields 67% Throughput Gain

In a recent project for a leading producer of specialty rolled products, Electronic Drives and Controls (EDC) successfully addressed a series of challenges stemming from an outdated Ruesch slitting machine control system. Characterized by obsolete hardware components, a complex operator interface, and difficulties in maintaining precise tension during steel slitting,