Operating a wire or cable production line can be complex and may include drawing, annealing, stranding, jacketing, spooling, and even packaging for final shipment. Despite the best practices and intentions, many things can go wrong.

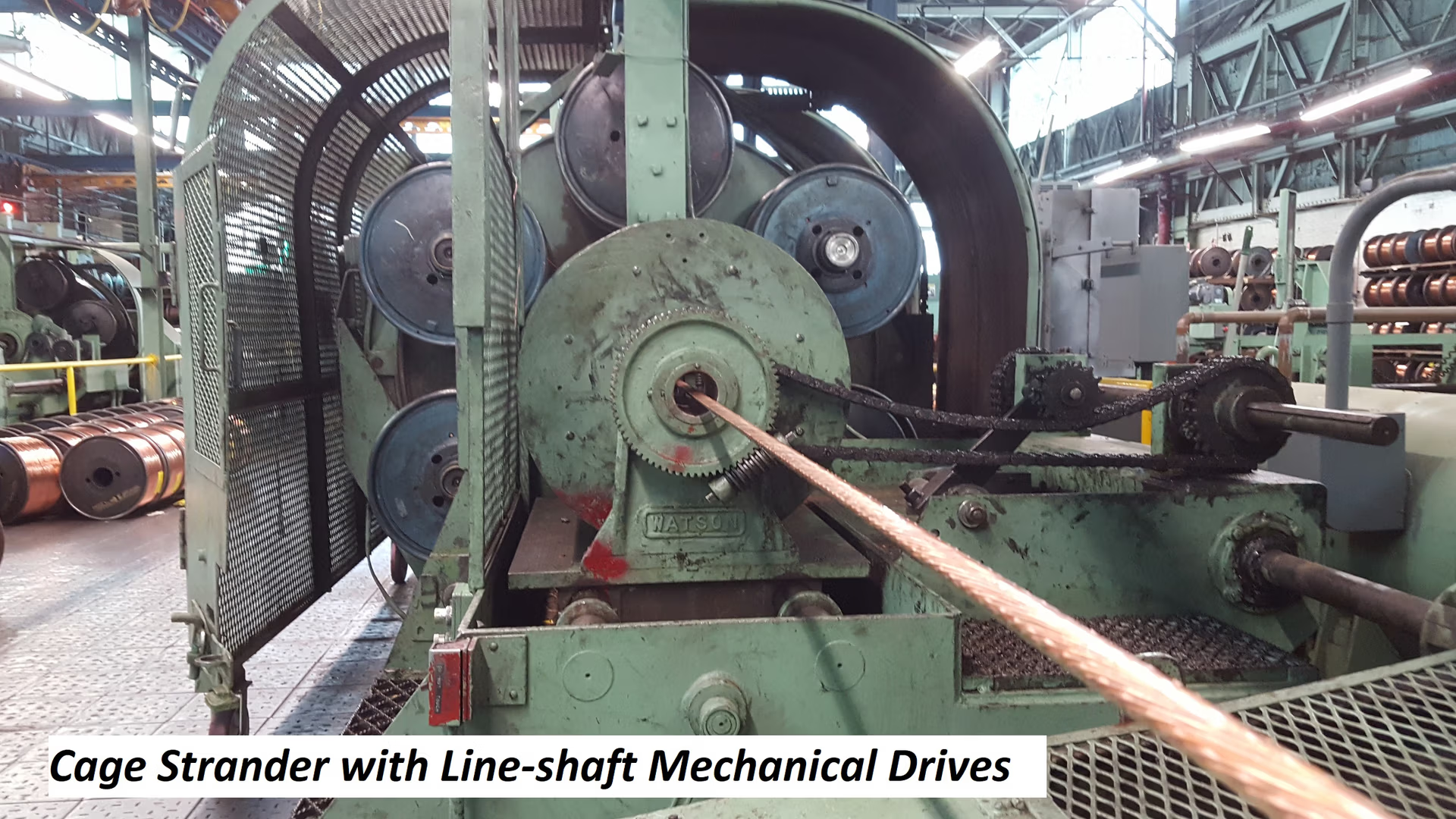

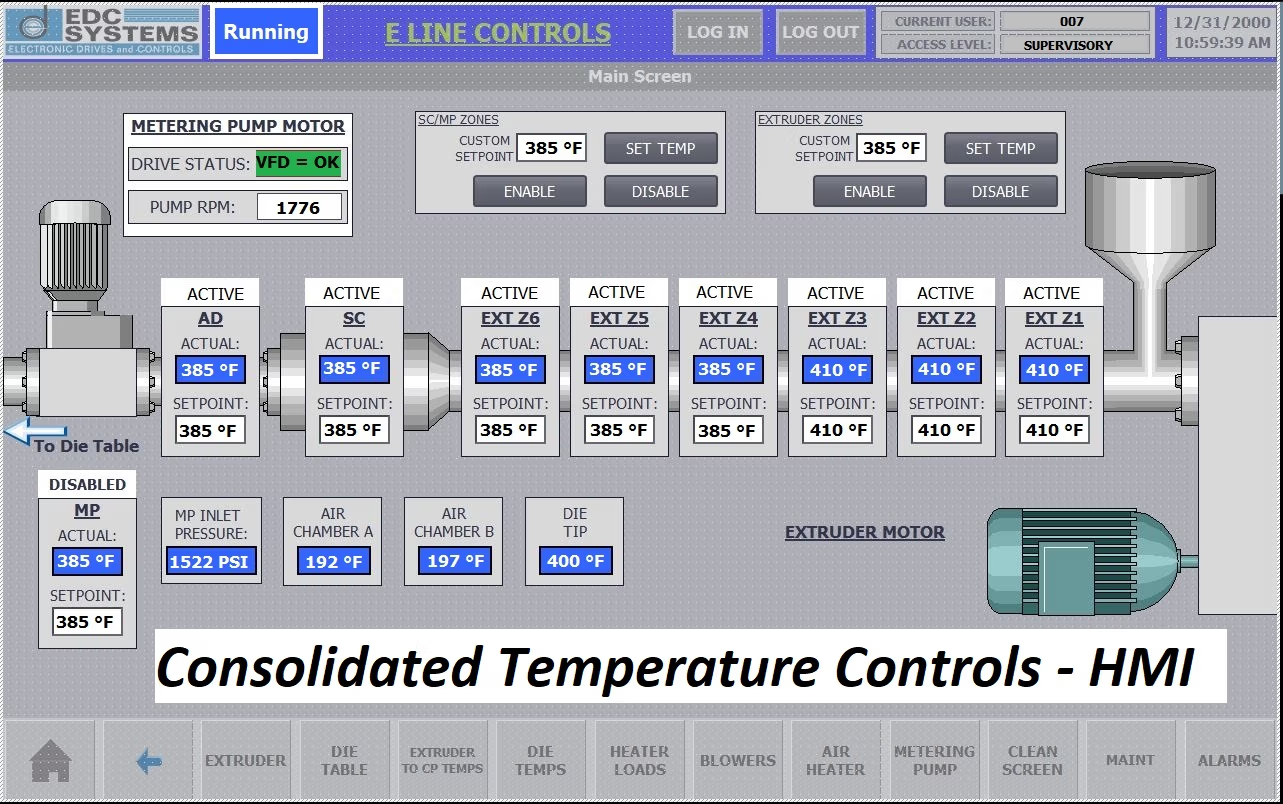

Wire and cable manufacturing encompasses many concurrent processes. The slightest problem, which sometimes goes undetected, can result in significant waste and rework. If your line goes down, troubleshooting and downtime can be costly. If your hardware is outdated and lacks advanced automation too, your production line may require much manual intervention. Any new operator must adjust to archaic displays that are not so user friendly.

Including advanced automation hardware and software, as well as implementing smart maintenance management, is best practice that can pay dividends. New automation control hardware and its programming are essential to not only meeting quality standards, but also for staying relevant in a globally competitive race for quality, cost, and speed of product delivery.

Your QC department rejects the spools coming out of the drawing machine for being too hard – a result of improper inline annealing. Your stripe extruder is creating a wider than desired color band and/or the jacketing is necking. Or maybe you’re just plain tired of excessive downtime and buying replacement parts on eBay. With so many complex processes inside of a modern Wire and Cable plant, there are scores of things that can go wrong. Here are a few more of the issues that EDC commonly finds hampering their customers’ success:

There are many ways to approach eliminating one or more of the above Wire and Cable pain points. Narrow down your process lines and determine which areas need the most attention first. Gather information from all sources to determine where to focus first and where to spend the most effort. Refer to hard facts, as well as anecdotal data from technicians and operators to do this most effectively.

Here are some ideas depending on the nature of the issue, the time available to address them and, of course, your budget.

Attack a specific component or two to relieve the pressure.

Stuff gets old. Components become incompatible. Long term exposure to the elements leads to material degradation. Dirt and grime cause all kinds of problems. Replacing just one item can make a world of difference.

HP = LINE SPEED (feet/min.) x TENSION (lbs.)

For motorized Pay-Offs and Take-Ups, multiply the resulting HP by the build-up ratio.

Annealers, Spoolers, Taping heads, Capstans, Accumulators – these are of course some of the sections of a wire and cable line that need coordinated components to function properly. You may not need to retrofit the whole line or may not have the time and money to do so. Perhaps you can focus on a single problem area:

So now it’s time to bite the bullet. No more band aids, no partial fixes. You have budgeted the funds and are building up enough stock to cover you for the line being down during the turnover demo/installation window. Despite the fear that you may be feeling, an expert systems integration firm will help ensure you get another 20+ years from the newly installed controls. A full retrofit can encompass some or all of the fixes recently cited plus the following:

Your Wire and Cable line keeps you up at night or away from home on the weekends. There are many relatively small steps you can take to take a bite out of the larger issue. And if need be or if it is just that time, you can retrofit the whole line without needing to install a more expensive, completely new line for a fraction of the cost and in less time.